SAS BTECH INDUSTRIE - 18 place des mésanges - 29300 QUIMPERLE - FRANCE - TEL: +33 (0)2 98 96 04 85 - MOBILE: +33 (0)6 64 69 97 23

KNEADERS - MIXER

MAINTENANCE, REPAIR, VENTE

CONTACT US

SAS BTECH INDUSTRIE 18 place des mésanges - 29300 QUIMPERLE - FRANCE +33 (0)2 98 96 04 85 +33 (0)6 64 69 97 23 Contact form http://www.btech-industrie.com

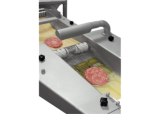

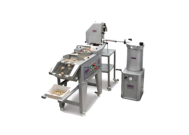

BATTER-BREADING

Batter-breading MOD. COMPACT / MINI / PRATIC-240 / PRATIC-350

Click on the picture to enlarge

Click on the picture to enlarge

Click on the picture to enlarge

Click on the picture to enlarge

MOD. COMPACT

MOD. MINI

MOD. PRATIC-240

MOD. PRATIC 350

Automatic battering and breading.

Useful width: 150 mm.

Speed: 10m per minute.

Production: 2.000 pieces per hour.

Motor power: 180 watts.

Single-phase electrical operation

(optional 120-220V, 50-60Hz).

Tabletop machine (table optional).

Can be fully dismantled for easy cleaning.

Made in stainless steel and suitable plastics for food industry.

Easy maintenance.

Low price.

Machine weight: 55kg.

Measurements of the machine when assembled:

1,000 x 485 x 400 mm.

Automatic battering and breading.

Output: 2,000 to 3,000 pieces per hour.

Speed variable from 9 to 15m per minute.

Useful width: 150mm.

Electrical operation (single-phase 220 volt).

Motor power: 250 watts.

Inverter for discharging bread.

Blower for excess liquid.

Pieces drop into the belt or go down ramp to remove excess bread.

Support for trays at exit.

Mounted on 4 legs with stainless steel wheels.

Can be fully dismantled for easy cleaning.

Made in stainless steel and non-toxic plastics

(suitable for the meat industry).

Maximum robustness and durability.

Easy maintenance.

Low price.

Machine weight: 110kg.

Measurements of the machine when assembled:

1,440 x 500 x 1,100 mm.

Measurements of the machine with packaging:

1,450 x 700 x 800 mm.

Automatic battering and breading.

Useful width: 240 mm.

Speed variable from 9 to 15m per minute.

Output: 3,000 to 4,000 pieces per hour.

Motor power: 370 watts.

Electrical operation (single-phase 220 volt).

Automatic bread feed.

Inverter for discharging bread.

Blower for excess liquid.

Plane output at a height of 960mm.

Mounted on 4 legs with stainless steel wheels.

Fully dismantlable for easy cleaning.

Made in stainless steel and non-toxic plastics

(suitable for the meat industry).

15-litre top-mounted batter tank.

Batter agitator.

30-kilogramme top-mounted breadcrumbs tank.

Maximum robustness and durability.

Easy maintenance.

Machine weight: 150kg.

Measurements of the machine when assembled:

1,990 x 680 x 1,640 mm.

Can optionally be fitted a turbine to blow the breadcrumbs

on the top side.

Automatic battering and breading.

Useful width: 350 mm (to order this can be 400 mm).

Speed variable from 9 to 15m per minute.

Output: 5,000 to 12,000 pieces per hour.

Motor power: 550 watts.

Electrical operation (single-phase 220 volt).

Automatic bread feed.

Inverter for discharging bread.

Blower for excess liquid.

Plane output at a height of 960mm.

Mounted on 4 legs with stainless steel wheels.

Fully dismantlable for easy cleaning.

Made in stainless steel and non-toxic plastics

(suitable for the meat industry).

30-litre top-mounted batter tank.

Batter agitator.

50-kilogramme top-mounted breadcrumbs tank.

Maximum robustness and durability.

Easy maintenance.

Machine weight: 200 kg approx.

Measurements of the machine when assembled:

1,985 x 880 x 1,640 mm.

Can optionally be fitted a turbine to blow the breadcrumbs

on the top side.

PETRINS - MIXERS

Petrin-mixer MOD. RM20

Petrin-mixer MOD. RC40

Petrin-mixer MOD. RC100

Click on the picture to enlarge

Click on the picture to enlarge

Click on the picture to enlarge

Ideal tabletop model for pilot plants

and artisanal productions.

Capacity of the tank in liters: 20 l.

Tank capacity in kg: ± 12 kg.

Transmission: very silent engine-gearbox group.

Engines:

Three-phase 0.33 HP / 0.24 kW

(230-400V 50Hz / 220V 60Hz)

Single-phase 0.33 HP / 0.24 kW

(230V 50Hz / 110-220V 60Hz)

Base dimensions: 39 x 27 cm

Construction: entirely in 18/10 stainless steel.

Ideal tabletop model for pilot plants

and small productions.

Capacity of the tank in liters: 40 l.

Capacity of the tank in kg: ± 25 kg.

Transmission: very silent engine-gearbox group.

engines:

Three-phase 0.75 HP / 0.55 kW (230-400V 50Hz / 220V 60Hz)

Single-phase 0.75 HP / 0.55 kW (230V 50Hz / 110-220V 60Hz)

Base dimensions: 56 x 38 cm

Construction: entirely in 18/10 stainless steel.

OPTIONS:

Traveling wheels.

Stainless steel support table

Model on feet, robust and reliable, for the average productions.

Capacity of the tank in liters: 95 l.

Capacity of the tank in kg: ± 65 kg.

Transmission: very silent engine-gearbox group.

engines:

Three-phase 1.75 HP / 1.29 kW (230-400V 50Hz / 220V 60Hz)

Single phase 1.75 HP / 1.29 kW (230V 50Hz / 110-220V 60Hz)

Base dimensions: 82 x 47 cm

Construction: entirely in 18/10 stainless steel.

OPTIONS:

Traveling wheels.

Petrin-mixer MOD. RM200

Petrin-mixer sous vide MOD.

TEC MAG ALFA 100

Petrin-mixeur sous vide MOD.

TEC MAG ALFA 150

click on the picture to enlarge

Ideal tabletop model for pilot plants

and small productions.

Capacity of the tank in liters: 40 l.

Capacity of the tank in kg: ± 25 kg.

Transmission: very silent engine-gearbox group.

engines:

Three-phase 0.75 HP / 0.55 kW (230-400V 50Hz / 220V 60Hz)

Single-phase 0.75 HP / 0.55 kW (230V 50Hz / 110-220V 60Hz)

Base dimensions: 56 x 38 cm

Construction: entirely in 18/10 stainless steel.

OPTIONS:

Traveling wheels.

Stainless steel support table

✓

Motor power of the blades: 0,75 kW

✓ Vacuum pump power: 0.75 kW

✓ Speed of the blades: 30 min. -1 (r.p.m.)

✓ Capacity of the container: 100 lts.

✓ Weight: 205 Kg.

✓ Made of AISI 304 stainless steel.

✓ Machine built according to the European Directive

89/392 EEC.

✓ Center arm type blade "T" with double direction of rotation,

suitable for kneading

all types of products and leave the ingredients perfectly.

✓ Suitable for 10-70Kg (According to product type)

✓ Transmission through gear motor.

✓ Appropriate to make the mass by removing the piercing arms

of the container.

✓ Very quiet and maintenance free.

✓ Locking system thanks to pedal for position dice

loading.

click on the picture to enlarge

click on the picture to enlarge

✓ Motor power of the blades: 1,5kW

✓ Vacuum pump power: 0.75 kW

✓ Speed of the blades: 30 min. -1 (r.p.m.)

✓ Container capacity: 150 lts.

✓ Weight: 390 Kg.

✓ Made of AISI 304 stainless steel.

✓ Machine built according to the European Director

89/392 EEC.

✓ Center arm type blade "T" with double direction of rotation,

suitable for kneading

all types of products and leave the ingredients perfectly.

✓ Suitable for 15-100Kg (According to product type)

✓ Transmission through gear motor.

✓ Appropriate to make the mass by removing the piercing arms

of the container.

✓ Very quiet and maintenance free.

✓ Locking system thanks to pedal for unloading position

Other models: contact us

MINCERS

Refrigerated mincer

MOD. MAP-ARTIC-LIGHT

Refrigerated mincer

MOD. MAP-ARTIC

Refrigerated mincer

MOD. MAP-ARTIC-CRYSTAL

click on the picture to enlarge

- Stainless steel construction AISI 304.

- UNGER double-cut body Ø H82 with

grille no. 3 fully removable

- Locking of the body by keying.

- Upper refrigerated reserve.

- High performance contact cooling,

temperature +1 °C / +5 °C class 3M1.

- Refrigerant R 134A / 100 grams.

- Steak portioner, size from 80 to 240 g,

without variation in thickness. Minced function

in a single gesture. PATENTED MAP SYSTEM

390 x 460 x 470 - 1405 W. - THREE-PHASE 400V

350 kg / Hour - weight: 49kg

Also available in 220 v MONO - 1850 W version

click on the picture to enlarge

- Stainless steel construction AISI 304.

- UNGER double-cut body Ø H82 with

grille no. 3 fully removable

- Locking of the body by keying.

- Large refrigerated upper storage tank

capacity.

- Cover made of ultra high polycarbonate

resistant.

- High performance contact cooling,

temperature +1 °C / +5 °C class 3M1.

- Refrigerant R 134A / 100 grams.

- Steak portioner, size from 80 to 240 g,

without variation in thickness. Minced function

in a single gesture. PATENTED MAP SYSTEM

440 x 485 x 540 - 1405 W. - THREE-PHASE 400V

350 kg / Hour - weight: 62 kg

Also available in 220 v MONO -1850 W version

.

- Stainless steel construction AISI 304.

- UNGER double-cut body Ø H82 with

grille no. 3 fully removable

- Locking of the body by keying.

- Large refrigerated upper storage tank

capacity.

- Steak portioner, size from 80 to 240 g,

without variation in thickness. Minced function

in a single gesture. PATENTED MAP SYSTEM.

- Stainless steel ground meat container.

- Cover and front door made of

ultra-resistant polycarbonate.

- Full ventilated cooling, temperature +1 °C /

+5 °C class 3M1.

- Refrigerant R 404A / 310 grams.

530 x 590 x 590 x 540- 1405 W. - THREE-PHASE 400V

350 kg / Hour - weight: 68 kg

Also available in 220 v MONO -1850 W version

.

click on the picture to enlarge

Refrigerated mincer

MOD. MAP-ARTIC-JUMBO

Mincer MOD. MAP-TC-12 / TC-22

Mincer MOD. MAP-TC-32X

click on the picture to enlarge

- Stainless steel construction AISI 304.

- UNGER double-cut system Ø B98 with

grid no. 4.5 (for other grids and knives, see

page 131).

- Body, propeller and knives completely

removable.

- Locking of the body by keying.

- Large refrigerated upper storage tank

capacity.

- Cover made of ultra high polycarbonate

resistant.

- Ventilated cooling, temperature +1 °C / +5 °C

class 3M1.

- Refrigerant R 134A / 100 grams.

- 380 V TRIPHASE power supply (3P+N+T).

450 x 530 x 570 x 570 -700 kg / Hour - weight: 84 kg

700 kg / Hour - 2510 w

click on the picture to enlarge

- Stainless steel body AISI 304.

- Body, knives, grids Ø 4,5 mm and screws

endless stainless steel removable.

- On / off by push button.

- Forward / reverse.

- Gear transmission.

- Ultra-fast disassembly of the body on

models "X".

- Three-phase 380 V power supply,

(SINGLE 230 V optional).

240 x 450 x 400 mm

weight: 26 kg - 250 Kg/h - 700 w

.

click on the picture to enlarge

- Stainless steel body AISI 304.

- Body, knives, grids Ø 4,5 mm and screws

endless stainless steel removable.

- On / off by push button.

- Forward / reverse.

- Gear transmission.

- Ultra-fast disassembly of the body on

models "X".

- Three-phase 380 V power supply,

(SINGLE 230 V optional).

260 x 530 x 620 mm - 600 kg / Hour

weight: 41 kg - 2210 w

.

Mincer MOD. PM-70 / PM-12

Mincer MOD. PC-82 / PC-22

Mincer MOD. PC-98 / PC-32

Available with two cutting systems of your choice:

ENTERPRISE 12 (single cut)

ENTERPRISE 70 (single and double cutting)

Construction: entirely in 18/10 stainless steel.

Transmission: by very quiet toothed belt.

Production: ± 170 kg/h.

Model recommended for short and intermittent production.

Ideal for shop or supermarket counters, for

its small size.

Engines:

Three-phase 1 HP / 0.74 kW (230-400V 50Hz / 220V 60Hz)

Single-phase 0.75 HP / 0.55 kW (230V 50Hz / 110-220V 60Hz)

Base dimensions: 21 x 27 cm

Tray dimensions: 31 x 41 cm

.

click on the picture to enlarge

click on the picture to enlarge

Available with two cutting systems of your choice:

ENTERPRISE 22 (single cut)

UNGER 82 (single, double and triple cutting)

Construction :

PC-82 / PC-22: entirely in 18/10 stainless steel.

PC-82A / PC-22A: in 18/10 stainless steel, except screws and mouth,

made of anodized aluminum.

Transmission: by gears immersed in oil.

Production: +/- 350 kg/h.

Engines:

Three-phase 1.5 HP / 1.1 kW (230-400V 50Hz / 220V 60Hz)

Single-phase 1.4 HP / 1.0 kW (230V 50Hz / 110-220V 60Hz)

Base dimensions: 31 x 41 cm

Tray dimensions: 31 x 41 cm

OPTIONS:

Large bin: 41 x 61 cm

Mouth protector with microphone, mandatory use to

from grids ³ 8 mm

.

click on the picture to enlarge

Available with two cutting systems

to your choice:

ENTERPRISE 32 (single cut)

UNGER 98 (single, double and triple cutting)

Construction: all steel i

noxidizable 18/10.

Transmission: by bathed gears

in oil.

Production: ± 800 kg/h.

Engines:

Three-phase 3 and 5 HP / 2.2 and 3.7 kW

(230-400V 50Hz / 220V 60Hz)

Single-phase 3 HP / 2.2 kW

(230V 50Hz / 220V 60Hz)

Base dimensions: 34 x 54 cm

Dimensions of the tray: 41 x 61 cm

OPTIONS:

Giant tray, larger: 49 x 69 cm

Mouth protector with microphone of

safety to be used on the

plates, with 8 mm holes.

.

Mincer MOD. PC-114L

Mincer- Mixer MOD. 95L

click on the picture to enlarge

click on the picture to enlarge

Available with UNGER 114 cutting system

(single, double and triple cutting)

Construction: entirely in 18/10 stainless steel.

Transmission: by gears immersed in oil.

Production: ± 1150 kg/h.

Engines:

Three-phase 5 HP / 3.7 kW (230-400V 50Hz / 220V 60Hz)

Base dimensions: 40 x 48 cm

Tray dimensions: 54 x 84 cm

OPTIONS:

Mouth protector with safety microphone to use

necessarily on the plates, with 8 mm holes.

.

Made of stainless steel.

Cutting system: Enterprise 32 (single cut)

/ Unger 98 (single, double and triple cutting).

Chopper motor power: 4 HP (3.00 Kw).

Mixer motor power: 1.75 HP (1.30 Kw).

Motor: three-phase 230/400V 50/60 Hz.

Transmission: oil gears.

Includes digital programmer with mixing cycles

and mixing and protecting mouth by mouth microphones.

First mincing production 1.500 kg/h approx.

Capacity in litres: 95 l.

Capacity in kg: approx. 65 kg.

Weight: 230 kg.

Base dimensions: 82 x 54 cm.

Total dimensions: 112 x 63 x 63 x 156 cm.

.

Other models: consult us

FORMERS MEATBALL / MINCED STEAK

Former chopped steaks and meatballs manual

MOD. RS 100 / RS 120 / RS 130 /

RS 55 / RB 25 / RB 38

+ Ideal for manually forming steaks

and meatballs

+ Fast and hygienic shaping

+ Models for steaks Ø 100 or Ø 130 mm

+ Models for meatballs Ø 25 or Ø 38 mm

- Robust anodized aluminum structure with legs

non-slip.

- Filling cylinder in stainless steel AISI 304.

- Cylinder capacity: 2.5 litres.

- Fully mechanical operation.

- Interchangeable polyethylene dies.

- Adjustable thicknesses up to 40 mm.

- Automatic ejection of the steak in front of the operator.

- Overall dimensions of the machine (W x D x H):

460 x 500 x 500 x 500 mm.

- Weight: 17 kg.

.

ADDITIONAL MATRICES IN OPTONS

Fomer chopped steaks and meatballs semi-automatic

MOD. MAP-STEAK-MATIC 100 / 130

click on the picture to enlarge

click on the picture to enlarge

ADDITIONAL MATRICES IN OPTONS

EXCISTE IN REFRIGERATED VERSION: CONTACT US

+ Ideal for quickly forming steaks

traditional chopped

+ Adjustable cadence by speed variator

+ Dies of different shapes or diameters

interchangeable

- Stainless steel, aluminium and

food polyethylene.

- Stable frame on non-slip feet.

- STEAK MATIC 100 : die Ø 100 mm included,

STEAK MATIC 130: standard matrix of your choice.

- Interchangeable dies for pellets,

sticks, steaks...*

- Steak thickness adjustment from 5 to 30 mm.

- Easy and fully functional

electromechanical.

- Variable speed drive controlling the rate.

- Safety protection on the cover and the

matrix.

- Low voltage controls 24 V / Device

CE certified.

- Power supply: SINGLE-PHASE 230 V.

.

Former chopped steaks and meatballs

automatic MOD. MAP-STEAK-MATIC-AUTO

Former chopped steaks automatic MOD.

SUPER-MAXI

+ Ideal for automatically forming steaks

traditional chopped

+ Steaks evacuated directly by the conveyor belt

+ Speed from 3000 to 5000 pieces / hour

-Stainless steel, aluminium and polyethylene construction

foodstuffs.

- Stainless steel frame, height to be defined when ordering.

- Food grade polyethylene rotating drum.

- Matrix for steaks Ø 100 or Ø 115MAXI included

(at your choice).

- Steak thickness adjustment from 5 to 30 mm.

- Easy operation and fully electromechanical.

- Adjustable cadence by means of a variable speed drive.

- Safety protection on the cover and die.

- Low voltage controls 24 V / CE certified device.

- Front emergency stop button.

- Power supply: SINGLE-PHASE 230 V.

click on the picture to enlarge

ADDITIONAL MATRICES IN OPTONS

EXCISTE IN REFRIGERATED VERSION: CONTACT US

ROUND PELLET CORRUGATORS: CONTACT US

Produces round steaks of Ø 50-120 mm and other shapes.

Speed: up to 55 steaks / minute and 110 steaks / minute in

in the case of double moulds.

Thickness: up to 25 mm with interchangeable moulds.

Steaks expelled by outside air.

Variable speed drive.

Tabletop machine.

Load capacity: 20 kg.

Recharging without the need to stop.

Made of stainless steel and suitable plastics.

Single-phase electrical current 220 V, 50-60 Hz, 1,100 W.

Optimizes up to the last 100 g of preparation.

800 m/m exit conveyor belt.

Can deposit 1 round, oval or square white paper.

Very easy to clean.

Measurements: 650 x 450 x 800 mm.

Weight: 85 kg.

Patented system.

click on the picture to enlarge

Former Automatic meatball

MOD. S-1500-P

Torque on all pushers (30 mm external diameter outlet)

It is the basic machine that allows, once coupled, to prepare

croquettes or cannelloni.

Produces up to 7,500 pellets (depending on press speed and

the type of dough). Changing the mould allows you to change the weight

(20-25-30 grams), on order we can reach

35 grams max. or 7 grams min.

Pneumatic operation at 6 kg / cm2.

Air consumption: 150 litres / minute.

Tabletop machine.

Easy to clean.

Does not require electrical power.

Measurements: 450 x 200 x 600 mm.

Weight: 25 kg.

Built in stainless steel.

click on the picture to enlarge

Former Automatic meatball

MOD. S-1500-PC

Can be torqued on all pushers (outlet with an external diameter of 30 mm).

Produces up to 7,500 pellets/hour (depending on press speed and

the type of dough). Changing the mould allows you to change the weight

(20-25-30 grams).

Produces up to 10,000 kibbles per hour (variable weight when changing

mould and outlet pipe) up to 60 g. With lower weights

at 30 g, the output can be double.

Pneumatic operation at 6 kg / cm2.

Air consumption: 150 litres / minute.

Tabletop machine.

Easy cleaning.

Does not require electrical power.

Weight of the croquette molding machine. 38 kg.

Measurements: 1,000 x 450 x 360 mm.

Built in stainless steel.

click on the picture to enlarge

Former chopped steaks automatic

MOD.V-3000-SP

Former chopped steaks automatic

MOD.V-3000-SP DOUBLE

click on the picture to enlarge

Can be used on all stamping machines.

Form hamburgers (without paper).

Produces 40 to 60 hamburgers per minute (depending on the speed of the stamping machine and type of dough).

Weight of hamburgers: from 25 to 300 grams (by changing the mould).

Variable shape (round, square, oval, rectangular). Round burgers from 60 to 110mm.

Pneumatic operation (consumes 250 litres / minute).

Working pressure: 6 kg / cm2.

Power consumption: 100 watts (3F).

Measurements: 1,200 x 600 x 620 mm.

Weight: 85 kg.

Made of stainless steel.

Can be used on all stamping machines.

Perfect for continuous press with dosing unit.

Produces up to 100 hamburgers / minute (2 per operation).

Weight of hamburgers: from 25 to 300 grams (by changing the mould).

Works without paper.

Variable shape (round, square, oval, rectangular). Round burgers from 60 to 110mm.

Diameter of hamburgers: from 70 to 110 mm.

Pneumatic operation at 6 kg/cm2 (300 litres/ minute).

Power consumption: 180 W (3 phases).

Measurements: 1,550 x 600 x 620 mm.

Weight: 125 kg.

Built in stainless steel.

click on the picture to enlarge

EXISTE EN MOD V-4000-SP

Former chopped steaks automatic

MOD.V-3000-CP

Former chopped steaks automatic

MOD.V-3000-CP DOUBLE

click on the picture to enlarge

Can be used on all stamping machines. Laying white paper or cellophane on one or both sides.

Paper consumption in rolls (possibly customized). Can work without paper.

Product from 40 to 60 hamburgers / minute

(depending on the speed of the stamping machine and type of pulp and whether or not paper is used).

Weight of hamburgers: from 25 to 300 grams (by changing the mould).

Cuts the paper to a fixed size of 106 x 132 mm.

Variable shape (round, square, oval, rectangular). Round burgers from 60 to 110mm.

Maximum permissible diameter 110 mm. Pneumatic operation at 6 kg / cm2.

Air consumption: 250 litres/ minute. Electrical power: 100 W. Tabletop machine.

Measurements: 1,300 x 600 x 620 mm. Weight: 85 kg.

Made of stainless steel.

Stacking stacker with 1 to 5 hamburgers (optional).

click on the picture to enlarge

Can be used on all stamping machines. Perfect for continuous press with dosing unit.

Produces up to 100 hamburgers / minute (2 per operation). Laying white paper or cellophane on one or both sides.

Consumes paper in rolls. Can work without paper. Cuts paper between 120 and 140 mm long.

Weight of hamburgers: from 25 to 250 grams (by changing the mould).

Variable shape (round, square, oval, rectangular). Round burgers from 60 to 100mm.

Pneumatic operation at 6 kg/cm2 (300 litres/ minute).

Power consumption 100 W (3 phases).

Double stacker stacker: from 1 to 5 hamburgers (optional).

Measurements: 2,250 x 600 x 620 mm.

Weight: 150 kg.

Made of stainless steel.

Other models: consult us

FILLERS

Hydraulic filler MOD. FC -12

Robust and reliable model, ideal for pilot plants

and artisanal productions.

Cylinder capacity in litres: 12 l.

Cylinder capacity in kg: ± 10 kg.

Engines:

Three-phase 0.6 HP / 0.44 kW (230-400V 50Hz / 220V 60Hz)

Single-phase 1 HP / 0.74 kW (230V 50Hz / 110-220V 60Hz)

All single-phase models are equipped with a ventilation kit

for better engine performance.

Three-phase models can also be equipped with it as an option.

Base dimensions: 41 x 47 cm

Construction: entirely made of 18/10 stainless steel, except cover

made of anodized aluminum and polyethylene piston.

Optional: 18/10 stainless steel cover.

click on the picture to enlarge

Hydraulic filler MOD. FC -20

Robust and reliable model, ideal for small productions.

Cylinder capacity in litres: 20 l.

Cylinder capacity in kg: ± 18 kg.

Engines:

Three-phase 1.25 HP / 0.92 kW (230-400V 50Hz / 220V 60Hz)

Single-phase 1.5 HP / 1.10 kW (230V 50Hz / 110-220V 60Hz)

All single-phase models are equipped with a ventilation kit

for better engine performance.

Three-phase models can also be equipped with it as an option.

Base dimensions: 41 x 47 cm

Construction: made entirely of 18/10 stainless steel, except cover and

piston, anodized aluminum.

Optional 18/10 stainless steel cover and piston.

The EI-20 INT & EM-20 INT versions have the

NSF / ANSI health certification 8.

click on the picture to enlarge

Hydraulic filler MOD. FC -25

Robust and reliable model, ideal for medium production.

Cylinder capacity in litres: 25 l.

Cylinder capacity in kg: ± 23 kg.

Engines:

Three-phase 1.75 HP / 1.29 kW (230-400V 50Hz / 220V 60Hz)

Single-phase 2.5 HP / 1.84 kW (230V 50Hz / 110-220V 60Hz)

All single-phase models are equipped with a ventilation kit

for better engine performance.

Three-phase models can also be equipped with it

as an option.

Base dimensions: 35 x 45 cm

Construction: entirely in 18/10 stainless steel, except cover and piston,

made of anodized aluminum.

Optional: 18/10 stainless steel cover and piston.

The FI-25 INT and FC-25 INT versions have the certification

health NSF / ANSI 8.

click on the picture to enlarge

Hydraulic filler MOD. FC -30

Robust and reliable model, ideal for medium productions.

Cylinder capacity in liters: 30 l.

Cylinder capacity in kg: ± 28 kg.

engines:

Three-phase 1.75 HP / 1.29 kW (230-400V 50Hz / 220V 60Hz)

Single-phase 2.5 HP / 1.84 kW (230V 50Hz / 110-220V 60Hz)

All single-phase models are equipped with a ventilation kit

forced, for better performance of the engine.

Three-phase models can also be equipped

optional.

Base dimensions: 35 x 45 cm

Construction: entirely in 18/10 stainless steel, except lid

and piston, made of anodized aluminum.

Optional: lid and piston in 18/10 stainless steel.

FI-30 INT and FC-30 INT versions are certified

NSF / ANSI sanitary 8.

click on the picture to enlarge

Hydraulic filler MOD. EI - 50

Robust and reliable model, ideal for medium productions.

Cylinder capacity in liters: 50 l.

Cylinder capacity in kg: ± 48 kg.

engines:

Three phase of 2.25 HP / 1.65 kW (230-400V 50Hz / 220V 60Hz)

Single-phase 2.5 HP / 1.84 kW (230V 50Hz / 110-220V 60Hz)

All EI-50 models, three-phase and single-phase,

equipped with a forced ventilation kit, for a

better engine performance.

Base dimensions: 54 x 54 cm

Construction: entirely in 18/10 stainless steel

(including lid and piston).

The EI-50 INT version has the NSF / ANSI 8 sanitary certification.

click on the picture to enlarge

Hydraulic filler MOD. EL - 12

click on the picture to enlarge

Built in stainless steel.

Lid and piston made of food plastic.

Capacity: 12 liters.

Engine power 375 watts.

Adjustable speed.

Automatic decompression of the cylinder.

230 V single phase current, 50 Hz.

Works without oil.

Removable cylinder and piston.

Output height: 1.090 mm.

Refueling cones Ø15, Ø20 and Ø30 mm.

Measurements: 488 x 370 x 1,128 mm.

Weight: 54 kg.

Hydraulic filler MOD. 20 L / 30 L / 50 L

Built in stainless steel. Removable cylinder for easy cleaning.

Internal piston in stainless steel and plastic. Plastic cover fixed by four columns.

Manometer pressure regulator.Flow regulator to obtain a constant speed.

Knee brace. Independent and cooled oil reservoir with level indicator.

Can be placed horizontally, resting on their back part. The upper part is disassembled

and allows to place the machine under a table.

24 volt controls.

Powerful device, guarantees a good operation with all products.

Support on two wheels and two fixed legs.

Hydraulic installation with high pressure hoses.

Automatic decompression of the cylinder.

Hydraulic cylinder with rod and nut in stainless steel.

Refueling cones Ø15, Ø20 and Ø30 mm.

Built-in oil.

Easy handling.

Minimal maintenance.

Mod. ECONOMICA 20L (750 watt motor, machine measurements: 501 x 371 x 1,200 mm, weight: 97 kg.)

Mod. ECONOMICA 30L (1000 watt motor, machine measurements: 541 x 406 x 1,207 mm, weight: 133 kg.)

Mod. ECONOMICA 50L (Engine 1470 watts, machine measurements: 591 x 476 x 1.220 mm, weight: 205 kg.)

click on the picture to enlarge

click on the picture to enlarge

Filler continuous vacuum MOD. EC - 120

Built in stainless steel AISI 304.

Meat feeding by 6-blade kneader.

Micro-protected vacuum group

capacitor.

Portion preparation

Knee lift height and adjustable position.

Hopper of 120 liters.

Easy cleaning.

Connects to our burgers molds, croquettes

of meat, croquettes, cannelloni and clippers

automatic.

3 Supply Cones 12-20-30 mm.

Tools and instructions.

Three-phase current 230/400 V 50/60 Hz.

Engine power: 2.5 kw.

Vacuum pump: 0.75 kw, 21 m3 / h.

Serving weight: 0 - 10,000 g.

Max production : 125 portions / minute (+/- 1g)

Free exit. 1500 Kg / h.

Weight: 190 kg.

click on the picture to enlarge

Other models: consult us

CUTTERS

Cutter MOD CM-14

click on the picture to enlarge

Cutter MOD CM-21

click on the picture to enlarge

Model on feet ideal for pilot plants

and small productions.

Capacity of the tank in liters: 22 l.

Capacity of the tank in kg: ± 15 kg.

Combined knife and bowl motors

Motor power knives:

1st speed: 4.0 HP / 2.9 kW

(1500 rpm at 50Hz and 1800 rpm at 60Hz)

2nd gear: 5.3 HP / 3.9 kW

(3000 rpm at 50Hz and 3600 rpm at 60Hz)

Motor power tank:

1st speed: 0.17 HP / 0.12 kW

(10 rpm at 50Hz and 12 rpm at 60Hz)

2nd gear: 0.24 HP / 0.18 kW

(20 rpm at 50Hz and 24 rpm at 60Hz)

Can work with 3 or 6 knives.

Equipped with 3 knives by default.

Base dimensions: 78 x 54 cm

Construction: entirely in 18/10 stainless steel

click on the picture to enlarge

Sturdy and reliable model on feet for

average productions.

Capacity of the tank in liters: 40 l.

Capacity of the tank in kg: ± 25 kg.

Combined knife and bowl motors

Motor power knives:

1st speed: 9 HP / 6.62 kW

(1500 rpm at 50Hz and 1800 rpm at 60Hz)

2nd gear: 11 HP / 8.09 kW

(3000 rpm at 50Hz and 3600 rpm at 60Hz)

Motor power tank:

1st speed: 0.47 HP / 0.35 kW

(10 rpm at 50Hz and 12 rpm at 60Hz)

2nd gear: 0.68 HP / 0.50 kW

(20 rpm at 50Hz and 24 rpm at 60Hz)

Can work with 3 or 6 knives.

Equipped with 3 knives by default.

Base dimensions: 90 x 64 cm

Construction: entirely in 18/10 stainless steel

Cutter MOD CM-41

Ideal table model for pilot plants and

artisanal productions.

Capacity of the tank in liters: 14 l.

Capacity of the tank in kg: ± 9 kg.

Combined knife and bowl motors

Motor power knives:

1st speed: 2.5 HP / 1.84 kW

(1500 rpm at 50Hz and 1800 rpm at 60Hz)

2nd gear: 3.5 HP / 2.57 kW

(3000 rpm at 50Hz and 3600 rpm at 60Hz)

Motor power tank:

1st speed: 0.12 HP / 0.09 kW

(10 rpm at 50Hz and 12 rpm at 60Hz)

2nd speed: 0.20 HP / 0.15 kW

(20 rpm at 50Hz and 24 rpm at 60Hz)

Can work with 3 or 6 knives.

Equipped with 3 knives by default.

Base dimensions: 70 x 48 cm

Construction: entirely in 18/10 stainless steel

Cutter MOD CM-41-S

Sturdy and reliable model on feet for

average productions.

This is the top version of the model

CM-41. She has knives at speed

variable and two mixing speeds

reversible at 80 and 150 rpm.

Capacity of the tank in liters: 40 l.

Capacity of the tank in kg: ± 25 kg.

Combined knife and bowl motors

Engine power knives

(with frequency converter):

12.5 HP / 9.19 kW

(variable speed from 1,000 to 3,600 rpm)

Motor power tank:

1st speed: 0.47 HP / 0.35 kW

(10 rpm at 50Hz and 12 rpm at 60Hz)

2nd gear: 0.68 HP / 0.50 kW

(20 rpm at 50Hz and 24 rpm at 60Hz)

Can work with 3 or 6 knives.

Equipped with 3 knives by default.

Base dimensions: 90 x 64 cm

Construction: entirely in 18/10 stainless steel

Cutter MOD CM-75-S

TECHNICAL SHEET

CONSULT US

click on the picture to enlarge

click on the picture to enlarge

Other models: consult us

BONE SAWS

Bone saw MOD. SEG-1600-V / SEG-1800-V

Robust and easy to use.

Cast aluminum construction

varnish, easy removal of the blade and pulleys,

worktable all stainless steel.

EC VERSION: meat grinder, sawing guide,

micro-switch

door security, electronic controls

with emergency stop,

low voltage and self-braking motor board,

motor protection cover.

EXPORT VERSION: sawing guide and meat grinder.

Bone saw MOD. SEG-1600-I / SEG-1800-I /

SGE-2400-I / SGE-3100-I

robust and easy to use. Stainless steel construction AISI304,

sawdust container blocked in the door, removable door for optimal hygiene.

Removable top pulley. Equipped with meat grinder, sawing guide,

door safety micro switch, low voltage motor board.

Aluminum pulley ..

click on the picture to enlarge

click on the picture to enlarge

Bone saw MOD. BC-1800

Construction: all steel

18/10 stainless steel, except anodised aluminum wheels.

Wheel diameter: 230 mm

Ribbon length: 1750 mm

Height of the cut: 230 mm

Width of the cut: 200 mm

engines:

Three phase of 1.25 or 1.5HP (230-400V 50Hz / 220V 60Hz)

1.5 HP single phase (230V 50Hz / 220V 60Hz)

The basic model includes a manual blade tensor,

a stop to adjust the thickness and a swivel pusher with

fixed intermediate support of the blade.

OPTIONS:

Automatic tensor of the blade.

Tank to collect the remains.

Half sliding cutting table with intermediate support

adjustable blade.

Floor stand in stainless steel.

Forced ventilation kit.

click on the picture to enlarge

Bone saw MOD. BC-2000

Construction: entirely in 18/10 stainless steel,

except cast iron steel wheels.

Wheel diameter: 275 mm

Ribbon length: 2120 mm

Height of the cut: 310 mm

Width of the cut: 233 mm

engines:

Three-phase 1.75 HP (230-400V 50Hz / 220V 60Hz)

1.5 HP single phase (230V 50Hz / 220V 60Hz)

The basic model includes a manual blade tensor,

a stop to adjust the thickness and a swivel pusher with

adjustable intermediate support of the blade.

OPTIONS:

Automatic tensor of the blade.

Tank to collect the remains.

Half sliding cutting table.

Floor stand in stainless steel.

Forced ventilation kit.

click on the picture to enlarge

Bone saw MOD. BC-2500

Construction: entirely in 18/10 stainless steel,

except cast iron steel wheels.

Wheel diameter: 300 mm

Ribbon length: 2520 mm

Height of the cut: 350 mm

Width of the cut: 280 mm

engines:

Three phase 2.5 HP (230-400V 50Hz / 220V 60Hz)

Single phase 2.5 HP (230V 50Hz / 220V 60Hz)

The basic model includes a manual blade tensor,

a stop to adjust the thickness, a swivel push with support

intermediate adjustable blade, a tank to collect

leftovers and a forced ventilation kit.

OPTIONS:

Half sliding cutting table.

Bone saw MOD. BC-3000

Construction: entirely in 18/10 stainless steel,

except cast iron steel wheels.

Wheel diameter: 300 mm

Ribbon length: 2520 mm

Height of the cut: 350 mm

Width of the cut: 280 mm

engines:

Three phase 2.5 HP (230-400V 50Hz / 220V 60Hz)

Single phase 2.5 HP (230V 50Hz / 220V 60Hz)

The basic model includes a manual blade tensor,

a stop to adjust the thickness, a swivel push with support

intermediate adjustable blade, a tank to collect

leftovers and a forced ventilation kit.

OPTIONS:

Half sliding cutting table.

click on the picture to enlarge

click on the picture to enlarge

Other models: consult us

SLICER

Vertical meat slicer

MOD. AF300VSC / AF300VS / AF330VS / AF350VS

AF370VS / AF380VS

click on the picture to enlarge

Recommended for small restaurants.

Compact dimensions with great cutting capacity.

Made of anodized aluminum fusion, belt transmission,

hardened and forged steel blade, carriage sliding on rings

self-lubricating, double sliding tray, aluminum sharpener

incorporated. The mod. AF300VSC is equipped with a closed heel lifter.

TECHNICAL SHEET MOD. AF300VSC / AF300VS / AF330VS

Vertical meat slicer silver MOD. AF350SVS /

AF370SVS / AF380SVS

click on the picture to enlarge

Vertical slicer recommended for professional use.

Made of anodized aluminum alloy melting,

belt drive, engine with thermal protection

(except 300 mm blade slicers), hardened steel blade

and forged, sliding of the trolley on self-lubricating rings,

sliding tray in both directions, release device

of the trolley (CE version), aluminum sharpener incorporated.

Available with anodized aluminum handles (Silver Version)

and with closed heel lifter (Armblock Version).

Vertical meat slicer with armblock

MOD. AF350VS+ABK / AF370VS+ABK /AF380VS+ABK

click on the picture to enlarge

Vertical slicer recommended for professional use.

Made of anodized aluminum alloy fusion, transmission

belt, motor with thermal protection

(with the exception of 300 mm blade slicers),

hardened and forged steel blade, sliding carriage

on self-lubricating rings, sliding tray in both directions,

Cart unlocking device (CE version), aluminum built-in sharpener.

Available with anodized aluminum handles (Silver Version)

and with closed heel lifter (Armblock Version).

Vertical meat slicer MOD. AF300VM /AF330VM /

AF350VM / AF370VM / AF380VM

Vertical meat slicer recommended for professional use.

Made of anodized aluminum alloy fusion, transmission

belt, motor with thermal protection

(with the exception of 300 mm blade slicers),

hardened and forged steel blade, carriage sliding on rings

self-lubricating, two-way sliding tray,

unblocking of the trolley (CE version), incorporated aluminum grinder.

Available with anodized aluminum handles (Silver version).

click on the picture to enlarge

Vertical meat slicer silver MOD. AF300SVM /AF330SVM

AF350SVM / AF370SVM / AFS380VM

click on the picture to enlarge

Vertical meat slicer recommended for professional use.

Made of anodized aluminum alloy casting, belt transmission,

motor with thermal protection (except 300 mm blade slicers),

hardened and forged steel blade, sliding carriage on

self-lubricating rings, sliding tray in both directions,

cart release device (CE version), aluminum sharpener

incorporated. Available with anodized aluminum handles (Silver version).

Vertical meat slicer verni MOD. AF300VM+VER /

AF330VM+VER / AF350VM+VER / AF370VM+VER /

AF380VM+VER

click on the picture to enlarge

Vertical meat slicer recommended for professional use.

Made of anodized aluminum alloy fusion, transmission

belt, motor with thermal protection

(except 300 mm blade slicers), hardened steel blade

and forged, sliding of the trolley on self-lubricating rings,

sliding tray in both directions, release device

of the trolley (CE version), aluminum sharpener incorporated.

Available with anodized aluminum handles (Silver version).

Belt gravity slicer MOD. AF220GRDOM / AF250GRDOM

AF250GRLDOM / AF275GRDOM / AF300GRCDOM

click on the picture to enlarge

Designed for small spaces. Fusion and anodized aluminum alloy.

Classic design. Belt training. Silent asynchronous motor,

hardened and forged steel blade, sliding carriage on self-lubricating bushes,

aluminum product tray with slides to reduce friction.

Embedded aluminum grinder.

DOM VERSION: blade guard with edge, safety micro-switch

disc cover blade, protection tray Plexiglass.

EXPORT VERSION: blade guard with edge.

click on the picture to enlarge

Gravity slicer MOD. AF220GR / AF250GRL /

AF275GR

Designed for small spaces. Fusion and anodized aluminum alloy.

Classic design. Belt training.

Silent asynchronous motor, hardened and forged steel blade,

sliding of the carriage on self-lubricating rings,

aluminum product tray with slides to reduce

friction. Embedded aluminum grinder.

Gravity slicer MOD. AF300GRC / AF300GR / AF300GRL /

AF300EGR / AF330GR

click on the picture to enlarge

Designed for small spaces. Fusion and anodized aluminum alloy.

Classic design. Belt training.

Silent asynchronous motor, hardened and forged steel blade,

sliding of the carriage on self-lubricating rings,

aluminum product tray with slides to reduce

friction. Embedded aluminum grinder.

Gravity slicer MOD. AF350GR / AF370GR

click on the picture to enlarge

Gravity slicers recommended for professional use.

Made of anodized aluminum alloy fusion, transmission

belt, motor with thermal protection steel blade

quenched and forged, sliding of the trolley on self-lubricating rings,

aluminum product tray with slides, device for

unblocking of the trolley (CE version), incorporated aluminum grinder.

Available with anodized aluminum handles (Silver version).

Belt gravity slicer silver MOD. AF300SGR / AF330SGR /

AF350SGR / AF370SGR / AF380SGR

click on the picture to enlarge

Gravity slicers recommended for professional use.

Made of anodized aluminum alloy melting,

belt drive, engine with thermal protection

hardened and forged steel blade, sliding carriage on

self-lubricating rings, aluminum product tray

with slides, cart release device (CE version),

aluminum sharpener incorporated. Available with handles

anodised aluminum (Silver version).

Gravity slicer with pinion MOD. AF300INGR /

AF350INGR

click on the picture to enlarge

Recommended use in large production.

Made of anodized aluminum alloy melting.

Sprocket drive to ensure continuous rotation

of the blade, which makes it possible to constantly press the

product during

the cup. Ventilated motor, all stainless steel screws,

hardened and forged steel blade,

sliding of the carriage on self-lubricating rings,

reduced inclination for firm and firm grip of the product to be cut,

larger product tray for greater cutting capacity, cart unblocking device,

aluminum sharpener incorporated.

Gravity slicer with pinion MOD. AF300INGR / AF350INGR /

AF300SINGR / AF350SINGR / AF300INGR+VER /

AF350INGR+VER / AF300TFLINGR / AF350TFLINGR

click on the picture to enlarge

Recommended use in large production.

Made of anodized aluminum alloy melting.

Drive by gears to ensure a continuous rotation of the blade,

which makes it possible to constantly press the product during cutting.

Ventilated motor, all stainless steel screw, tempered and forged steel blade, sliding

trolley on self-lubricating bushings, reduced inclination for firm grip

and solid product to cut, larger product tray for a

larger cutting capacity, cart unblocking device,

aluminum sharpener incorporated.

TECHNICAL SHEET MOD. AF300INGR / AF350INGR / AF300SINGR /

AF350SINGR / AF300INGR+VER / AF350INGR+VER / AF300TFLINGR / AF350TFLINGR

Automatic slicer MOD. AF300GRSA /

AF350GRA

click on the picture to enlarge

Automatic slicers, anodized aluminum alloy melting,

easy to use, high cutting capacity and efficiency.

Available in two versions:

AF300 GR A: compact dimensions, recommended for small

and average restoration. Belt training,

manual or automatic operation.

AF350 GR A: robust and recommended for professional use,

recommended use in supermarkets. Training by gears,

two engines

(one for the movement of the carriage and the other for

the rotation of the blade),

stainless steel tray and heel pusher, tempered and forged steel blade,

built-in aluminum sharpener, slicing programming to be cut

with automatic machine shutdown (slice counter),

3 speed settings, 3 carriage stroke settings.

Vertical meat slicer top MOD. AF350VSTOP /

AF370VSTOP

New slicers designed for large production,

result of the knowledge and direct relationship with

experts and distributors.

Rounded shape and new technical design.

Belt drive, ventilated motor, GB blade, all stainless steel screws,

anodized aluminum handles, built-in sharpener with tray,

stainless steel edge protector, increased and removable grease guard,

large distance between the blade and the blade support pulley.

Sliding tray in both directions,

Armblock heel pusher with demountable pusher,

truck unlocking device and safety micro-switch

disc cover blade.

IP67 buttons. Option: RAL color varnish

Vertical meat slicer top MOD. AF350VMTOP /

AF370VMTOP

click on the picture to enlarge

New slicers designed for large production,

result of the knowledge and the direct relationship with the experts

and distributors. Rounded shape and new technical design.

Belt drive, ventilated motor, GB blade, all stainless steel screws,

anodized aluminum handles, built-in sharpener with tray,

stainless steel edge protector, increased and removable grease guard,

large distance between the blade and the blade support pulley.

Two-way sliding tray, Armblock heel pusher

with demountable pusher, cart unlocking device

and micro-switch disc security covers blade. IP67 buttons.

Option: RAL color varnish.

Vertical slicer with belt top MOD. AF350GRTOP /

AF370GRTOP

New slicers designed for large production,

result of the knowledge and the direct relationship with the experts

and distributors. Rounded shape and new technical design.

Belt drive, ventilated motor, GB blade, all stainless steel screws,

anodized aluminum handles, built-in sharpener with tray,

stainless steel edge protector, trolley release device,

Disk security micro-switch covers blade, IP67 buttons.

The new slice thickness plate design and distance

between the blade and the motor, allow easy cleaning.

Option: RAL color varnish.

click on the picture to enlarge

click on the picture to enlarge

Manual slicer with steering wheel MOD. AF250VOL /

AF300VOL / AF350VOL / AF370VOL

Elegant style, home-made.

The flying slicer is particularly suitable for

the cut of ham. Made of aluminum, stove enamelled,

parts in contact with food in stainless steel. Blade protection ring,

ease of disassembly to allow complete cleaning.

Fully manual, built-in sharpener

Gravity slicer shabu MOD. AF300SH / AF350SH

click on the picture to enlarge

Trancheurs gravité recommandés pour l’usage professionnel,

idéal pour couper toutes sortes de produits congelés.

Réalisé en fusion d’alliage d’aluminium anodisé, transmission à courroie,

moteur asynchrone silencieux, lame dentée en acier trempé et forgé,

coulissement du chariot sur bagues autolubrifiantes, plateau porte-produit

en aluminium avec glissières. Le système de régulation de l’épaisseur modifié,

permet de couper des tranches fines 1 mm de toutes sortes de viande

ou produits congelés (-6°C / +4°C).

Other models: consult us

click on the picture to enlarge

VARIOUS MACHINES FOR MEAT

Semi-automatic tying machine MOD. T-70

Type of knotting: continuous thread.

Consumes coils of wire (cone-mounted).

Pneumatic operation (4 kg / cm2).

Does not need electric power.

Air consumption at normal speed (80 liters / minute)

Knee control with attachment for automatic tying.

Entry 54 mm.

Adjustable choke.

Variable speed from 50 to 140 op./minute.

Tying with 3 turns.

Table mounted machine (650 x 500 x 700 mm table with stainless steel wheels).

Easy cleaning.

Measures 650 x 380 x 420 mm.

Weight: 42 kg.

Built in stainless steel.

click on the picture to enlarge

Portioner-Twister MOD. PR-360

The new PR-360 Portioner-Twister is a machine

formidable that will undoubtedly change the lives of many

small and medium producers of sausages.

Make the most of your sausage pusher

thanks to this equipment.

You can now portion and twist the hoses

while filling them.

An affordable solution that will save you money

in time and skilled labor.

You will depreciate it very quickly, without realizing it.

Just adjust the portion size

(between +/- 20g and +/- 1000g), select the operating mode ...

and you will be ready!

Estimated production: +/- 1 portion per second

(up to 360kg / hour)

Suitable for use with natural intestines,

in collagen, polyamide or cellulose.

Equipped with 3 stainless tips of 12, 15 and 17 mm

outside diameter. Optional 11 and 20 mm.

Construction: 18/10 stainless steel and polyethylene.

Complies with CE standards. The PR-360 INT model

is NSF compliant

click on the picture to enlarge

Portion cutter MOD. L-80

Strangle and cut the fresh sausage.

Production: 100 to 400 pieces / minute.

For natural or artificial gut.

Length of parts on the L-80 standard: 100, 120, 140, 160, 180 mm

Length of parts on the special L-80: 160, 180, 200, 240, 280 mm.

Diameter of sausages: from 10 to 35 mm.

Manual operation (5 pieces per pass).

Table machine.

Constructed of stainless steel and non-toxic plastics (for the meat industry).

Easy cleaning and maintenance.

Weight of the machine: 10 kg.

Measurements of the packaged machine: 570 x 510 x 240 mm

click on the picture to enlarge

click on the picture to enlarge

Construction: stainless steel.

Inner tilt band with adjustable speed.

The portions are adjustable, variable length or

by changing the mouthpiece.

Paper consumption: coils.

Perfect presentation of the product.

Cutting paper and meat portion: manual.

Electric power: 370 watts max.

Single phase electric current: 230 V, 50/60 Hz.

Measures: 470 x 360 x 500 mm.

Weight: 50 kg.

POSSIBILITY OF PORTIONS OF SPICY GROUND MEAT,

IN PILLOWS OR CYLINDERS (With paper support)

POSSIBLE FITTINGS WITH STRIPPER OR CHOPPER 98:

- For all connections, the maximum length is 220 mm

and the maximum thickness of the pellets or cylinders

of meat is 30 mm.

- For servings of minced meat, the thickness

depends on the output of the chopper.

CONNECTED TO THE DRIVER:

- Can form pellets or cylinders from 100 to 115 mm

width according to order.

CONNECTED TO THE HACHOIR 98:

- With wire outlet the width of the portion is 115 mm.

- With single molding nozzle for tablet (width 80 mm).

- With special molding nozzle for pellet or cylinders

(width from 100 to 115 mm according to order).

Construction: stainless steel.

Inner tilt band with adjustable speed.

Width of the output band: one meter, adjustable in height.

Portions are adjustable, variable length or changing

the mouthpiece.

Paper consumption: coils.

Perfect presentation of the product.

Cutting paper and meat portion: automatic.

Operation: pneumatic (6 kg / cm2).

Air consumption: 100 liters / minute.

Electric power: 370 watts max.

Single phase electric current: 230 V, 50/60 Hz.

Measures: 470 x 360 x 600 mm.

Weight: 69 kg.

POSSIBILITY OF PORTIONS OF SPICY GROUND MEAT,

IN PILLOWS OR CYLINDERS (With paper support)

POSSIBLE FITTINGS WITH STRIPPER OR CHOPPER 98:

- For all connections, the maximum length is 220 mm

and the maximum thickness of the pellets or cylinders

of meat is 30 mm.

- For minced meat portions,

the thickness depends on the output of the chopper.

CONNECTED TO THE DRIVER:

- Can form pellets or cylinders from 100 to 115 mm

width according to order.

CONNECTED TO THE HACHOIR 98:

- With wire outlet the width of the portion is 115 mm.

- With single molding nozzle for tablet (width 80 mm).

- With special molding nozzle for pellet or cylinders

(width from 100 to 115 mm according to order).

click on the picture to enlarge

click on the picture to enlarge

Compact machine to install on a table

Production up to 300 kg / hour

Loading and frontal collection

4 or 5 fillets per breast

Active security systems

80W electrical power

Electric current 230V, 50 / 60Hz

Dimensions: 530 x 430 x 340 mm

Weight: 60 kg

Built in stainless steel

Noise: sound pressure level: less than 70dB (A)

Compact machine to install on a table to cut

breasts of any type with a production reaching

300 kg / hour.

Loading and collecting the chest on the same side.

click on the picture to enlarge

Built in stainless steel.

Table machine.

Pneumatic operation.

For all guts.

Regulator closing and pressure.

Uses TX-10, 12, 14, 16 staples.

Magazine capacity: 220 staples.

Air pressure: 6 kg / cm2.

Air consumption per operation: 3.3 liters.

Measures: 250 x 370 x 700 mm

Weight: 25 kg.

made of stainless steel.

Manual operation.

Table machine.

For all guts.

Regulator closing and pressure.

Uses TX-10, 12, 14, 16 staples.

Magazine capacity: 220 staples.

Measures: 370 x 250 x 700 mm.

Weight: 20 kg.

click on the picture to enlarge

Built in stainless steel.

Table machine.

Pneumatic operation.

Double staple and cut in the center.

Regulator closing and pressure.

For any type of rosary closure (thread between the 2 ends).

Uses TX-10, 12, 14 staples.

Loader capacity: 440 staples.

Air pressure: 6 kg / cm2.

Air consumption per operation: 3.6 liters.

Measures: 250 x 500 x 700 mm.

Weight: 26 kg.

Fully autonomous machine

Production up to 1,000 units / hour

For skewers Ø3,8 and 120 mm up to 300 mm long

Skewers with adjustable length and format

Automatic cleaning

Pneumatic operation at 6 bar (kg / cm2)

Air consumption of 20 liters / minute

400W electrical power

Electric current 230V, 50 / 60Hz

Measurements: 1305 x 1130 x 1320 mm

Weight: 120 kg

Built in stainless steel

Noise: sound pressure level: less than 70dB (A)

Fully automatic machine, electrically operated

and pneumatic for the production of skewers with a production

maximum of 1,000 kebabs per hour. The same machine allows

to produce different product formats by changing the length of the skewer.

click on the picture to enlarge

Cooking pot designed for hot preparation of all types of creams,

sauces, bechamel, etc.

It has a thermal chamber to transmit the heat so

uniform to the preparation in a similar way to the "bain-marie",

thus avoiding that the creams come into contact with the thermal resistances.

The bowl is made of 316 high quality stainless steel in thickness

3 and 5 mm, to guarantee a perfect functioning during all the useful life

of the machine. The rest of the construction is entirely made of steel

stainless type 304.

For the preparation of the cream, the tank has a stirrer-breaker

which prevents the formation of lumps, as well as lateral scrapers and

bottom to prevent the product from sticking.

To facilitate cleaning, the tank has no internal elements that hinder

this process. Optional: tank with outlet valve for non-pasty products.

Motorized tilting for more dense products.

High power and high efficiency machine due to the isolation chamber

thermal that avoids heat loss.

Power supply 380/400 V three-phase.

Operating temperature up to 200ºC Electronic control

Time programmer and cooking temperature.

Inverter of direction of rotation of the agitator and the variator of speed.

Motorized tilting of tank.

Power 21 kW.

click on the picture to enlarge

You are looking for other models of machines for meat: contact us

Maintenance, Installation, Sales, Consulting & Training

HYDRAULIC HOSES ASSISTANCE

INDUSTRIAL MAINTENANCE

MACHINERY & EQUIPMENT

© 2022 btech industrie